All about the lab…

The solid media lab

We have two large presses within the School of GeoSciences for simulating high pressure/temperature conditions of planetary interiors, in addition to a range of supporting equipment. These, and the lab I work in, form part of the NERC Recognised Experimental Geoscience Facility.

Solid-media (piston cylinder) presses and hydraulic system.

Juergen Schleppi using the atmospheric furnace to cast synthetic lunar glass.

Both presses house end-loaded piston-cylinder devices capable of routinely reproducing conditions up to 4 GPa and 1650°C. Both 0.5″ and 0.75″ sample assemblies can be used, and we use a range of assembly designs to simulate various conditions. The labs are supported by an excellent mechanical workshop….in fact, a large amount of equipment, including one of the presses, was designed and built in-house.

Our larger blue (500 tonne) press (top image) can also house a Walker Cell multi-anvil unit for simulating higher pressure conditions, although we currently use the press largely for piston-cylinder experiments due to high workload in the lab and the availability of a 1000 tonne multi-anvil apparatus in the School of Chemistry.

In addition, the lab houses a range of support equipment, including various furnaces and ovens, polishing and sample preparation facilities, analytical balances and a PUK U4-TIG impulse micro welder. Included within these are a suite of gas-mixing furnaces which allow samples to be annealed up to 1850°C within controlled atmospheres. A combination of CO2, H2 and Ar gases can be flowed through sealed tubes within furnaces (using mass flow controllers) to impart a range of reducing or oxidising conditions. Rapid insertion and quenching enables short duration annealing experiments and production of glasses.

Deltec gas-mixing furnace with rapid sample insertion and quenching.

Analytical facilities at Edinburgh

The School of GeoSciences is home to a range of facilities which we use quite heavily, including equipment which constitutes the Edinburgh Materials and Micro-Analytical Centre (EMMAC). This includes a Cameca SX100 electron probe and Carl Zeiss SIGMA HD Field Emission Scanning Electron Microprobe, both of which enable routine but high-resolution sample analysis and characterisation. My group are also regular uses of the NERC Ion Microprobe Facility (EIMF), also housed within the School of GeoSciences. This suite of Secondary ion Mass Spectrometers can be used for high resolution chemical analysis of run products down to ppm levels, and for isotopic characterisation. More generally, the School and wider University house an impressive array of research equipment for sample characterisation.

Wider links

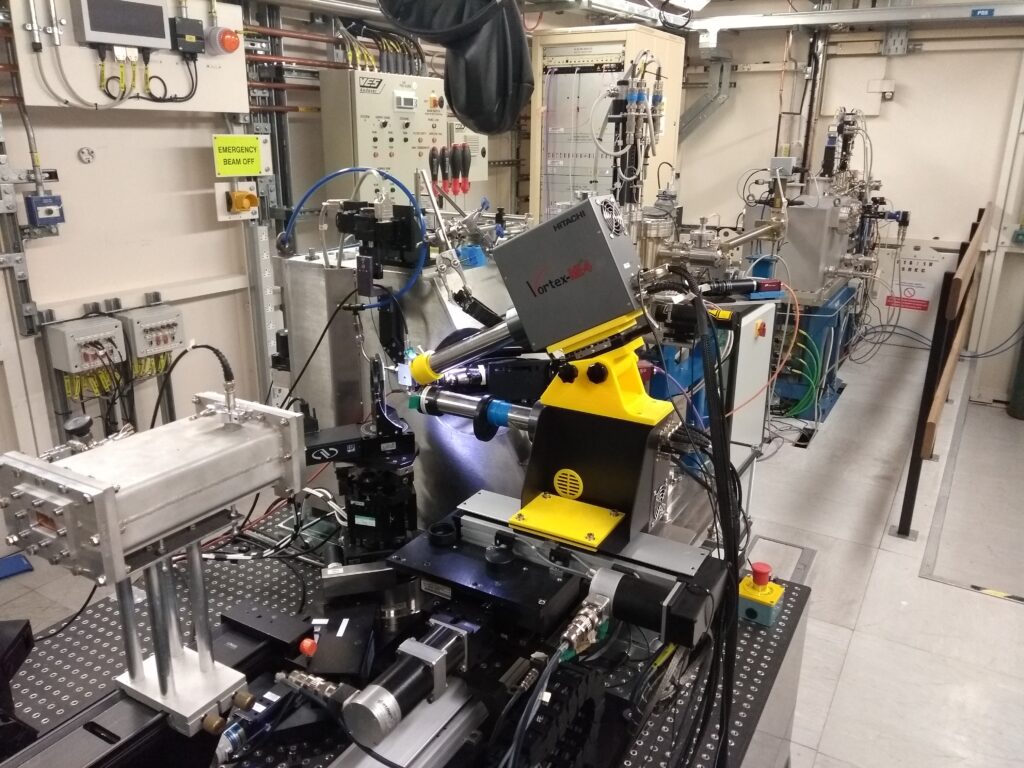

Much of the work that the group does involves use of external facilities. In-situ experiments can be performed at facilities such as the extreme conditions ID27 beamline at the European Synchrotron radiation Facility (ESRF), where synchrotron radiation can be used to obtain diffraction data, or 2-D and 3-D ‘images’ from samples whilst they are held under extreme conditions, using specially designed large-volume presses. Synchrotron radiation can also be used for detailed sample characterisation. X-ray absorption spectroscopy, for example, can be used to determine local bonding environments and the oxidation state of a range of elements within materials synthesised under planetary conditions. The i18 beamline at the the Diamond UK synchrotron facility permits micro-resolution analysis of run products.

The i18 spectroscopy beamline at the Diamond synchrotron facility.

Comments are closed

Comments to this thread have been closed by the post author or by an administrator.