The processes of producing inkstick

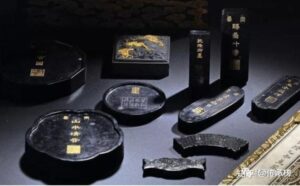

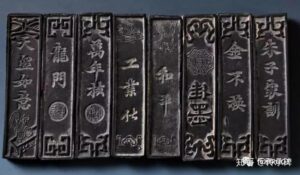

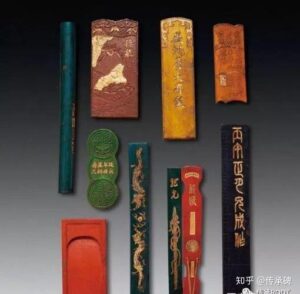

Inksticks or ink cakes are a kind of solid ink, which is made in a traditional Chinese processes and used as one of the most significant material in calligraphy and brush painting. Main materials of inksticks are soot, animal glue and something with incense or medicinal scents. And they looks as following pictures I put.

Then I am going to introduce the main processes of making inksticks.

First, burning and collecting soot.

The tung oil used in oil refining fume is extracted from the squeezed fruit of the tung tree that has been grown for more than 3 years. The smoking room for refining oil fume needs to be airtight. Damp grass is used to light the oil lamp, Each lamp is covered with a porcelain bowl and smoked in the bowl. The finer the bituminous coal particles, the better the quality and vice versa.

Second, blending materials.

Blending is an important step in making inksticks. It refers to the process of mixing soot and glue into an ink blank. The mixing ratio of soot and glue is generally 2:1.

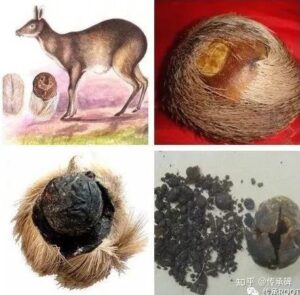

Something with incense or medicinal scents will also put in. Animal musk and plant borneol are precious materials that are valued.

musk

musk

borneol

borneol

Third, making inksticks.

After the kneaded material is made into an ink blank. It will start to grind and knead after a part of the water has evaporated.

The most important thing in ink making is beating. The handwork ensure that the ink is made to achieve the goal of no gaps on the surface and no bubbles inside, and the blank is beaten into a uniform texture.

Fourthly, putting in a mold.

After weighing, the ink stick is fully kneaded into a cylindrical shape, and then placed in the ink mold for pressing, the pattern on the ink mold will be printed on the surface of the ink stick.

Fifthly, hanging up and drying.

The ink drying room should maintain constant temperature and humidity, and it should also prevent cracking and mildew according to the changes of the seasons. At the same time, the ink should be constantly turned over to restore the smoothness of the naturally arched ink body during drying and shrinking.

Sixth, Trimming.

When the inkstick is shaped in the mold, the gap of the mold causes the ink stick to have some stubble. The worker needs to cut the stubble with scissors to make the ink more regular.

Seventh, waxing and coloring.

Eighth, packaging.

Recent comments