It’s time to retire our Combined Heating and Power plants.

In this article, Professor David Jordan, Director of Sustainability for the School of Mathematics, discusses the challenges and opportunities for providing low-carbon heating and power to University campuses.

Once a win-win solution on climate and costs, our CHP plants have run their course.

For the past twenty years or so, the University of Edinburgh has run its own power plants right here on campus – in Kings Buildings, in George Square, and at Pollock Halls. Fuelled by methane, these “combined heating and power” (CHP) plants work by capturing waste heat from the generation of electricity and redirecting it to heat the radiators of nearby buildings in a process called cogeneration.

CHP plants have been championed by environmentalists for decades, and for good reason: they emit far less carbon than the coal plants which pre-dominantly powered the national grid in years past. They were also much cheaper for the university to run than buying grid electricity — they were the rare win-win.

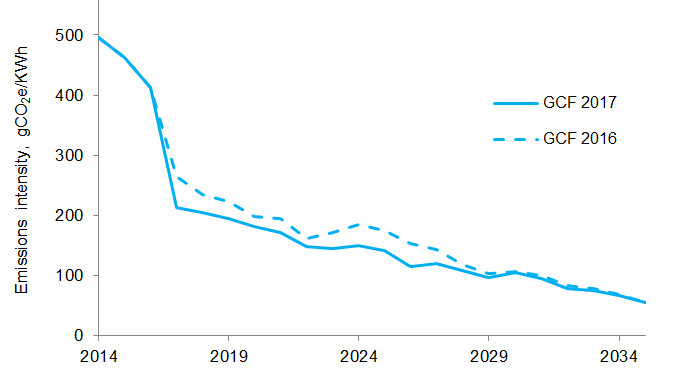

Around the year 2016 CHP plants became obsolete. Today, CHP plants emit far more carbon to the atmosphere than grid electricity, even once the bonus heat from cogeneration is accounted for. This obsolescence in fact stems from several breakthroughs in the national energy context: coal plants in the UK have been almost completely shuttered or convereted to biomass; meanwhile wind, solar and nuclear power now account for around half of the UK’s power generation, and all run with essentially zero greenhouse emissions¹. Indeed, even the gas power stations which make up the remainder of our national power generation use a “combined cycle gas turbine” (CCGT) mechanism which effectively matches² the efficiency gains of CHP cogeneration. In short, the UK grid electricity has decarbonized by an astonishing 80% in the past decades, while the carbon intensity of CHP has held steady.

The tumbling carbon intensity of grid electricity

It is not only in the production of electricity that the CHP is holding back our carbon ambitions. Ironically, the CHP plant’s defining virtue – its provision of heat through cogeneration – is now its most urgent shortcoming. The future of UK district heating lies in heat pumps which provide low-carbon heating from grid electricity, however we cannot begin the important transition on our campuses until the CHP plant is laid to rest.

There is no viable counterargument: the CHP plants running in the Kings Buildings, Pollock Halls, and George Square campuses have ceased to be consistent with our commitment to decarbonising our university. It is time to plan to phase them out, in Edinburgh, and on campuses nationwide.

The University should be proud of its forward-thinking approach when these were first installed and should especially take pride in the hundreds of thousands of tonnes of carbon emissions saved by running these plants over two decades. The University must also recognize, however, that the times have changed. The CHP plants were installed in the first place due to the active engagement of expert academic staff in engineering who advocated for their installation. It is now time for the University to rely again upon its academic expertise and heed the call to transition away from these plants.

Here are the numbers on emissions.

In 2018, the University undertook an audit of its energy production and consumption, in preparation for the Energy Master Plan. The resulting data tells an unambiguous story, and it does not look good for the CHP.

The efficiency of a power plant is quantified by its “carbon intensity”. This measure is simply the ratio of the mass of carbon emitted per unit of electricity produced, typically reported in grams CO2 equivalent per kilowatt hour, abbreviated gCO2e/kWh. Here “CO2 equivalent” refers to the impact of greenhouse gases other than carbon dioxide, scaled relative to CO2. A particularly important point to note is that methane gas which powers the CHP is approximately 80x as potent a greenhouse gas as CO2.

By comparing the carbon intensity of a local power station to the publicly reported grid average carbon intensity, we can easily determine the relative efficiency of our power stations.

I go into the numbers in gory detail in my discussion paper here, but here are the headline numbers as pertain to the Kings Buildings plant. Once the bonus heat from cogeneration is accounted for, the CHP plant in Kings Buildings produces a whopping 366gCO2e/kWh, compared to the grid average of 113gCO2e/kWh. This means that our CHP plant produces fully three times as much carbon as the national average, resulting in more than 8000 tonnes additional CO2e emissions each year, as compared to grid-provided electricity. For scale, the average UK citizen consumes around 10 tonnes for their entire annual carbon budget. Another point of comparison is that the total emissions for the University come in at around 73,000 tonnes CO2e across electricity, heat, water, waste, travel and university vehicles. This means that powering down the CHP in Kings Buildings alone would result in an 11% cut to our University’s emissions. Doing likewise in George Square and Pollock Halls would reduce our total emissions by a full 27%. This is not marginal – this is substantial!

The alternatives to CHP are neither far-flung nor futuristic.

The most remarkable thing about the CHP plants at this moment is how easy they would be to replace. Indeed, because of their age, they fail constantly and require urgent repairs. They are already offline for significant stretches, during which the university simply buys power directly from the grid and provides heat through industrial gas-fired boilers. There would be no disruption, no capital investment, and no risk to simply powering them down. It could happen tomorrow.

Doing so would open the door to the most important next step in the University’s decarbonisation: adoption of heat pumps. Heat pumps are fascinating inventions, something like an air-conditioner run in reverse, and with miraculous thermodynamic properties which allow for extraction of heat energy from a priori “cold” environmental sources — the outside air, the earth, even computing banks and sewage pipes. Heat pumps deserve their own blog post, and there’s nobody better than our own Daniel Friedrich to give it. But the long story short is that, with a relatively small initial capital investment, heat pumps can and should replace our industrial gas-fired boilers, and would effectively cut a further 3300 tonnes from our annual CO2e emissions. Far from futuristic, heat pumps are low-tech, were developed in the 1850’s, and have been commonplace worldwide since the 1960’s. The only thing that has changed recently is the rapid decarbonising of electricity, on which heat pumps run, which has suddenly made them both economically and environmentally essential to decarbonising heating nationwide.

The CHP is still a cost-saver for the University, but this is changing.

Make no mistake, a CHP plant is (for now) still much cheaper for the university to run than buying grid electricity and maintaining heat pumps. There are many causes to this: holdover subsidies from the government encouraging adoption of CHP, a concentration of green tariffs on electricity but not on methane, and complicated balancing and grid maintenance fees levied on grid electricity consumers. All told, the cost savings annually to the University by running CHP plants is on the order of millions pounds per year. This is a significant cost savings, and anyone advocating for a change in policy must contend with the gap such a shift would leave in our budget.

The landscape with tariffs and subsidies is changing, however. The UK government has announced that it is targeting CHP subsidies for termination in the coming years, an acknowledgment of their obsolescence in the carbon landscape. As one example, balancing fees – fees charged by the grid to all customers to address economic and technological fluctuations in power supply and demand – will now be charged to all grid customers per electricity consumed, whether it is on-site or off-site. This will add between 1-2p/kWh of electricity produced on-site. As another example, the grid has historically engaged small plant operators during the “triads” – the peak three times per year for electricity demand – to run their stations and sell back to the grid at premium rates. This practice is ending. In the coming few years, we can expect the government’s position on CHP to keep evolving, and to make them less and less affordable to run. At the same time, the government is providing new funding for large institutions looking to transition to heat pumps.

Subsidies and tariffs aren’t all. Our CHP plants have long outlived their life cycle, and they are in constant need of upkeep and repair. A full accounting of the cost-savings provided by the plants must include the costs on repairs, as well as the man-power and regular maintenance provided by our staff. This expertise can be instead directed elsewhere to provide carbon and cost savings all around our campus.

To read more about the argument for retiring the CHP, please see my discussion paper found here.

Footnotes:

- This however neglects the embedded carbon cost of constructing the plants and, especially in the case of a nuclear power plant, in decommissioning it.

- CHP plants running under optimal conditions produce 0.4kWh of electricity and additionally 0.4kWh of heat per kWh fuel consumed. CCGT plants produce approximately 0.6kWh of electricity per kWh of energy consumed, while industrial boilers produce approximately 0.9kWh of heat for every kWh energy consumed. Thus, in order to produce 0.4kWh electricity plus 0.4KWh of heat from a CCGT and an industrial boiler, we must consume 1.11kWh of power, or 10% more fuel than is required for a CHP plant running at full efficiency. This assumes however that all heat produced by the CHP plant is required on-site; if any heat is wasted (or if due to an excess of heat in the system, buildings are allowed to be heated inefficiently) then the balance tips in favor of CCGT. In 2018, approximately 20% of heat produced via CHP in Kings Buildings was expelled to the atmosphere.

(Photograph of King's Buildings CHP plant taken by Magnus Hagdorn, Scotland UK)

Recent comments