Applied Geoscience Laboratory Consultancy

The Edinburgh University Applied Geoscience Laboratory for Sustainable Energy provides specialised experimental investigations into the secure and sustainable use of the subsurface for low carbon energy applications including hydrogen energy storage, CO2 storage, CAES and geothermal systems.

The brochure of the laboratory services offered can be found @ UoE_Hydrogen_CO2_AppliedGeoscienceLaboratory_CommercialServices_2024

For all enquiries on how we can help please contact Katriona Edlmann

Email: katriona.edlmann@ed.ac.uk

Facilities include:

High PT Geochemistry Reaction Vessels

- Multi-phase geochemical reactions for hydrogen and CO2 at in-situ elevated temperatures, fluid types, and pressures.

- Constant pressure monitoring, with fluid and gas sampling supported by full rock, gas and fluid analysis.

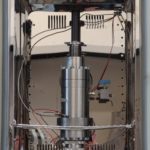

THMC Multiphase Flow Rig

- Multi-phase flow through 38mm diameter rock samples over a range of reservoir temperatures, fluid types (including hydrogen and scCO2), brine chemistries, fluid pressures and confining stress, equivalent of up to 4km depth.

- Constant pressure and permeability monitoring with fluid and gas sampling pre- and post- rock contact, supported by full rock, gas and fluid analysis.

- Relative permeability and wettability measurements.

multiphase flow rig

1m Hydrogen Gas Flow Rig

- Gas flow through a 1m long sandstone core at elevated temperatures and pressures combined with a Hiden HPR20 mass spectrometer to characterise breakthrough curves for hydrogen (and other gasses).

- Breakthrough curves can be used to determine: advective velocity; mechanical dispersion; molecular diffusion and sorption of hydrogen during mass transfer through porous reservoir sandstones.

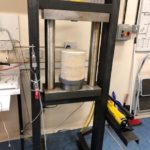

Unconfined Loading Rig

- Designed to look at creep and deformation in large (200mm diameter) rock samples, in particular the creep of salts for hydrogen storage in salt caverns and determine Uniaxial Compressive strength (before and after gas exposure.

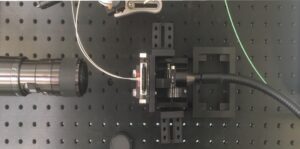

High-Pressure Micromodel Experiments

- Glass micromodels with different pore networks and wettability.

- Possibility to use real rock thin section micromodels.

- Multi-phase of hydrogen and CO2 at in-situ elevated pressures, and multiphase flow.

- Constant pressure and flowrate monitoring, supported by image analysis.

- Contaminant transport investigations.

- Microbial activities and biofilm growth experiments.

- Evaluation of effect of fluid properties on the multiphase flow (Viscosity, Density, Salinity)

- Evaluation of Surface properties on fluid flow properties (Wettability).

- Micro-scale evaluation of surface interactions of different fluids.

Micro-CT Investigation of Fluid Flow through Rock

- Multi-phase of hydrogen and CO2 at in-situ elevated pressures, and multiphase flow.

- Constant pressure and flowrate monitoring, supported by 3D image analysis.

- Digital rock experiments.

- Evaluation of effect of various 3D structures on flow properties

Rock, Gas and Fluid Analysis – Provided at the School of Geosciences

- Quantitative whole-rock analysis, including:

- X-ray Fluorescence (XRF)

- X-Ray Diffraction (XRD)

- Inductively Coupled Plasma Spectrometry

- Organic Geochemistry

- Thin Section and Sample Preparation

- Imaging, microscopy and photo-microscopy

- Optical Microscopes

- X-ray microCT

- Scanning Electron Microscope (SEM)

- Electron Probe Microanalysis (EPMA) Facility

Comments are closed

Comments to this thread have been closed by the post author or by an administrator.