Dimple He & Jieqiong Zhang

I. Pre-Recording Preparations

- Project Background

The primary objective of this recording expedition is to conduct an on-site exploration of an abandoned paper factory and capture its distinctive industrial sound sources. These audio materials will serve as the foundation for subsequent sound processing, visual interaction, and sound design, with applications in film, video games, and experimental music.

- Equipment Selection

To capture a diverse range of sounds, we selected the following recording equipment:

- Microphones:

- Sennheiser MKH416 (Shotgun Microphone): Focused sound capture with minimal environmental noise interference.

- S&K Contact Microphone: Captures vibrations from objects, such as metal pipes and machine casings.

- Soundfield ST250 Ambisonic Microphone: Used for immersive spatial recording (not fully utilized due to equipment limitations).

- Recording Devices:

- Zoom F8 Field Recorder: Multi-track recording with high dynamic range support.

- Rode 3m Boompole: Provides flexibility in microphone positioning.

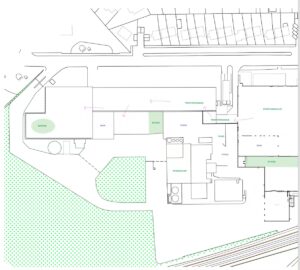

- Site Assessment

(1) Acoustic Characteristics

The factory’s internal structure and materials shape its unique sonic characteristics:

- Workshop: An open space filled with metal and machinery, producing strong low-frequency resonance and multiple reflections—ideal for recording industrial noise and metal impact sounds.

- Food & Bar Area: Likely features low-frequency hums from fans and heating equipment with a background of human activity, suitable for ambient recordings.

- Performance Stage: The high ceiling creates pronounced echoes, perfect for capturing long reverberations and eerie, atmospheric sounds.

- Office & Mess Room: Enclosed spaces with sound-absorbing materials, minimizing echoes—ideal for clean background recordings.

(2) Environmental Noise

- External Noise: The factory has multiple open entrances, allowing for potential interference from wind and traffic sounds.

- Structural Noise: Residual machinery and pipes may generate subtle metallic clanks or low-frequency resonances due to temperature changes or wind exposure.

(3) Floor Materials

- Concrete Flooring: Strong sound reflections, suitable for capturing dull reverberations.

- Metal Grates/Steel Flooring: Produces metallic resonance and may emit creaking sounds due to rust or structural wear.

- Wood Flooring (less common): May produce creaks due to aging, adding a vintage atmosphere to the recordings.

- Challenges & Opportunities

(1) Main Challenges

- Noise Control: Uncontrollable environmental noise may interfere with recordings, requiring selection of optimal recording times (e.g., early morning or during low wind periods).

- Wind Noise Issues: Some recording locations are exposed, necessitating the use of windshields (Deadcat) to minimize interference.

- Equipment Protection: Dust and humidity could affect recording gear, requiring additional protective measures.

(2) Recording Opportunities

- Unique Environmental Sounds: The factory’s residual metal resonances, machinery hums, and wind sounds provide a rich palette for sound design.

- Immersive Recording Possibilities: The layered sonic textures—ranging from hallway echoes to pipe vibrations—help create a dynamic, multi-dimensional soundscape.

II. The Recording Process

- Recording Methods & Key Locations

We used multi-point recording, combining various techniques to capture a comprehensive sonic profile:

- Ambient Sound Recording:

- Placed ambisonic microphones at different locations to capture spatial atmospheres.

- Used stereo microphones for wide spatial depth.

- Targeted Sound Recording:

- Shotgun microphones focused on mechanical impacts and metal rail sounds.

- Contact microphones attached to metal pipes, door frames, and machinery casings to record vibrational audio.

- Interesting Sounds Discovered

- Footsteps on Different Surfaces: Walking on concrete, metal grates, and wooden floors simulated various environmental settings.

- Metal Gate Impact Sounds: The gate’s bounce-back effect created rich high-frequency reverberations.

- Decayed Conveyor Belt Sliding: Producing a dull, elongated resonance, evoking an industrial past.

- Cart Wheels Moving: Simulated aging tool friction with layered sonic textures.

- Wind Moving Through a Roll-Up Door: Unexpectedly mimicked the sound of an old machine’s slow operation.

- Unexpected Challenges & Adjustments

(1) Contact Microphone Issues

- Narrow Pickup Range & Sound Uniformity

- Solution: Experimented with different placement points and supplemented recordings with ambient microphones.

- Handling Noise & Vibration Interference

- Solution: Secured microphones properly, reduced cable movement, and monitored recordings with headphones.

- Weak or Distorted Signals

- Solution: Used a high-impedance preamp (Zoom H6) to amplify signals while avoiding overload.

III. Post-Recording Processing & Analysis

- File Organization & Preliminary Analysis

After recording, I categorized and archived files by environment and sound type (e.g., metal impacts, footsteps, ambient atmospheres). Each recording was labeled with details like equipment used, recording method, specific location, and time for easy reference.

Listening back, I analyzed sound quality, noise interference, volume consistency, and microphone performance. For contact mic recordings, I examined resonance characteristics and signal clarity to determine their usability. Surprisingly, subtle details—like the slow metallic hum of a closing door or wind-induced tremors in metal sheets—became more apparent during playback.

- Unexpected Discoveries

- Metal Cart Friction Sounds: Initially recorded as simple rolling noise, playback revealed intricate wheel vibrations and internal part rattles, adding realism.

- Wind-Induced Metal Door Vibrations: The strong wind in the empty factory created a low-frequency mechanical hum, mimicking an old machine coming to life—perfect for cinematic and game sound effects.

- Decayed Conveyor Belt Sliding: Generated a nostalgic mechanical resonance, reminiscent of a once-bustling factory.

- Improvement Strategies

(1) Equipment Adjustments

- Microphone Selection: The contact mic recordings suffered interference; upgrading to a higher-quality preamp could improve signal strength and clarity. More use of the Soundfield ST250 Ambisonic Microphone would enhance spatial depth.

- Wind Protection: Future recordings could benefit from advanced windshields (e.g., Rycote Deadcat) to reduce wind noise artifacts.

(2) Recording Techniques

- Multi-Point Recording: Instead of using a single mic per sound, I plan to position multiple microphones around the same source (e.g., different angles of a metal gate impact) to capture varied perspectives.

- Dynamic Recording: Instead of only static placements, moving microphones through space could reveal more realistic sound transitions.

(3) Timing & Environmental Adjustments

- Selecting Quieter Recording Periods: Early morning or late-night sessions would reduce external noise interference.

- More Interactive Sound Experiments: Beyond passive recordings, I could manipulate materials (e.g., striking metal pipes) to create richer industrial sound effects.

IV. Personal Reflections & Future Plans

1. Most Satisfying Recordings

- Metal Gate Reverberations: The layered metallic echoes captured a sense of history and decay, ideal for industrial and sci-fi settings.

- Conveyor Belt Sliding: The blend of frictional noise and deep resonance evoked a strong sense of industrial nostalgia.

2. Key Takeaways

- The Role of Space in Sound: Hard surfaces amplify resonance, while soft materials absorb it—essential knowledge for future environmental recordings.

- Microphone Suitability: Shotgun mics are directionally focused but sensitive to background noise, while contact mics capture internal vibrations but are prone to handling noise.

- Unexpected Sounds Add Value: Spontaneous elements, like wind-induced metal tremors, often provide the most compelling audio textures.

3. Future Applications

- Sound Design: Use these recordings for film, game, and industrial ambiance creation.

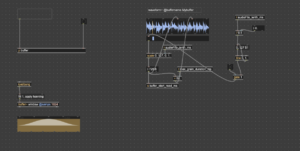

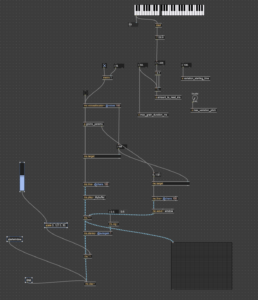

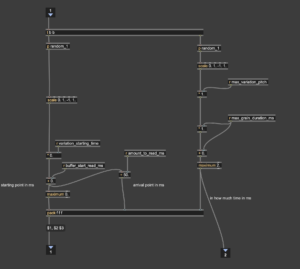

- Experimental Music: Process the sounds with granular synthesis, reverb, and delay for artistic projects.

- Immersive Audio: Explore Ambisonics to create a virtual abandoned factory soundscape.