When it comes to printing onto fabric, there are lots of available options, from traditional methods such as Block and Screen Printing to modern techniques like Digital and Sublimation Printing. Each technique has it’s own unique aesthetic and characteristics, as well as pros and cons.

What method you choice to use will largely depend on fabric choice. In some cases you can combine techniques, to create interesting and dynamic textiles.

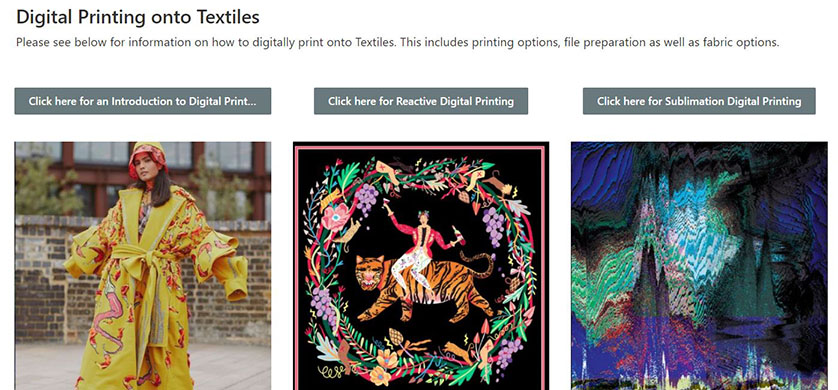

Here we will cover the main types of printing digitally:

Transfer Printing

This technique allows you to digitally print onto fabric, from home. Imagery is printed onto specialist paper, called Transfer paper, through either inkjet or laser print household printers. Once a design is printed onto the transfer paper, it is transferred onto fabric with a steam iron.

Transfer paper can be purchased online and in shops making it easily accessible. This printing method will leave a shiny film/surface to your fabric, and is not classed as a permanent method of printing, as it can crack, peel and fade with time.

Pros

- Accessible printing method

- No specialist equipment needed

- Great for sampling/small runs

- Easy to print and transfer

Cons

- Leaves a shiny film/texture to the fabric

- Single use transfers

- Limited life span; peels, cracks and fades with time/washes

- Limited print quality and resolution as well as colour range

Dye Sublimation

Sublimation printing is a sophisticated alternative to transfer printing. A multi-step process, this printing process is suitable for synthetic based fabrics.

Designs are first digitally printed onto thermal transfer paper called Dye Sublimation paper. This paper is then used to print onto fabric through the use of heat and pressure, permanently bonding the inks on paper to the fibres of the fabric. This step is usual done by using an industrial heat press. Once you’re fabric has been printed, it is set and ready to use. As this process uses dyes, the fabric retains it’s original characteristics.

Pros:

- Digitally prints are permanent, colourfast & washable

- Dye-based inks allow for a wider colour range and colour brightness

- Soft handle and feel to fabric, with original fabric characteristics retained

- No post-treatment required

- Minimal ink and no water wastage

Cons:

- Not for use on natural fabrics

- Specialist equipment and dyes required

Reactive Printing

Reactive or digitally printing as we call it, is for digitally printing onto natural based fabrics.

This process uses Reactive dyes, which are suitable for printing onto both cellouse (plant) and protein (animal) based fibres. These dyes require fabric to be treated with a specific pre-treatment before printing. Pre-treated or coated fabric, is rolled and loaded onto a digital printer for printing. Imagery is printed when ink passes through the machine’s printer head, in a similar way to an inkjet printer. Once printed, ink is fixed to the fabric through a Steamer. This moist heat causes the inks to react and bond with the fabric. To complete the process, fabric is washed to remove the pre-treatment coating and any excess dye. Once washed, fabric is ready to use.

Pros:

- Digitally prints are permanent, colourfast & washable

- Dye-based inks allow for a wider colour range and colour brightness

- Soft handle and feel to fabric, with original fabric characteristics retained

- Inks penetrate fabrics’ extremely well

- Minimal ink wastage

Cons

- Not for use on synthetic fabrics, natural and pre-coated only

- Fabric requires pre-and post-treatment

- Specialist equipment and dyes required

Pigment Printing

Pigment printing allows you to print onto most fabric types, including natural and synthetic, making it a popular and versatile printing technique. Designs are printed onto fabric and are set to the fabric using a dry heat, usually through a heated roller or Heat Press machine.

Pros

- Print onto a wide range of fabrics in a variety of weights

- No fabric pre-treatment necessary

- No water or specialized fixation, steaming or washing process required.

Cons

- Pigments sit on top of a fabric’s surface rather then being embedded into the fibres.

- Pigment binder leaves a coating on top of the fabric

- Colour range not as wide as with dye-based inks

As you can see there is a wide range of digitally printing options available, some more accessible than others with their own unique pros and cons. Currently within ECA we offer Reactive and Sublimation digital printing. Whilst we don’t offer digital pigment or transfer printing, we can offer support and guidance with these techniques for anyone interested. Remember you can always get in touch by emailing textiles@ed.ac.uk to speak to one of our textile techniques.